How is it made?

Aluminium composite is generally produced through a continuous rolling process, in which:

- Two thin aluminium sheets are bonded to a central core (made of polyethylene, fireproof mineral material or other high-performance polymers).

- Everything is compressed and bonded with high-strength technical adhesives.

- A surface finish, such as powder coating or PVDF coating, is applied to improve durability and aesthetics.

Features of composite aluminium

The main features that make aluminium composite a versatile and innovative material include:

- Lightness-much lighter than traditional metal materials, facilitating transport and installation.

- High mechanical strength-Thanks to its layered structure, it offers superior strength, flexibility and durability.

- Corrosion resistance-does not easily oxidise and resists weathering.

- Good workability-can be cut, bent and shaped with ease.

- Thermal and acoustic insulation-Based on the composition of the core, it can offer good thermal as well as acoustic insulation.

Application Sectors

L'alluminio composito è ampiamente utilizzato in diversi settori industriali, tra cui:

Aerospace

In the aerospace industry, it is used to make lightweight and strong structural components, helping to improve aerodynamic performance and reduce fuel consumption. An example of its use can be found in the construction of the Space Shuttle, where some secondary components use aluminium composite to reduce the overall weight and improve the reliability of the structure.

Aeronautics

In the aircraft industry, aluminium composite is used for the construction of aircraft interior and exterior panels, providing an optimal balance between weight and strength. A practical example is the Boeing 787 Dreamliner, several interior panels of which are made of aluminium composite to reduce weight and improve aircraft efficiency.

Railway Sector

In railways, it is used for interior and exterior panels, helping to reduce the overall weight of trains and improving energy efficiency. A case in point is the use in Japanese Shinkansen trains, which use aluminium composite to reduce the weight of carriages and optimise speed and energy consumption.

Building and Architecture

Aluminium composite is one of the most widely used materials for façade cladding, roofing and architectural decoration due to its resistance to weathering and the variety of finishes available. A well-known example is the Burj Khalifa in Dubai, the world's tallest skyscraper, which uses aluminium composite panels in its structure to ensure durability and lightness. Composite materials are increasingly used in construction, with applications ranging from reinforcing concrete to creating structural insulating panels (SIP).

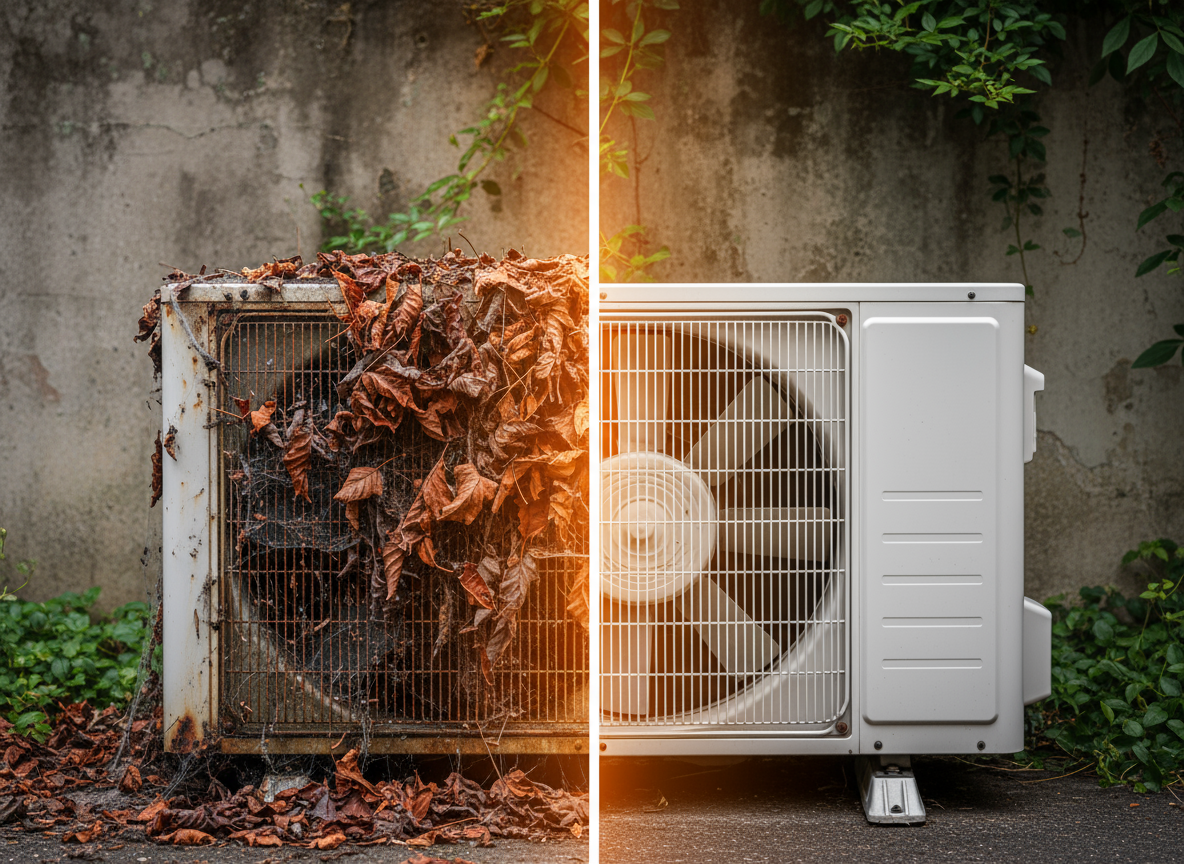

Composite aluminium for the protection of heat pumps and outdoor units

Composite Aluminium is also widely used in the field of outdoor unit covers. Covering outdoor units improves the design of outdoor environments and safeguards the performance of heat pumps and air conditioning systems. Box Air Klima is a leader in the production of covers for outdoor units, 100% made in Italy and professionally manufactured with composite aluminium.

If you are interested in protecting your heat pump discover Box Air Klima products at www.boxairklima.com