The change of season and your heat pump

With autumn around the corner, home becomes our refuge again and the heat pump enters its most delicate period: after cooling for months, it now has to deliver heat consistently and efficiently. The transition isn’t automatic: it requires a few small checks to prepare the system for winter.

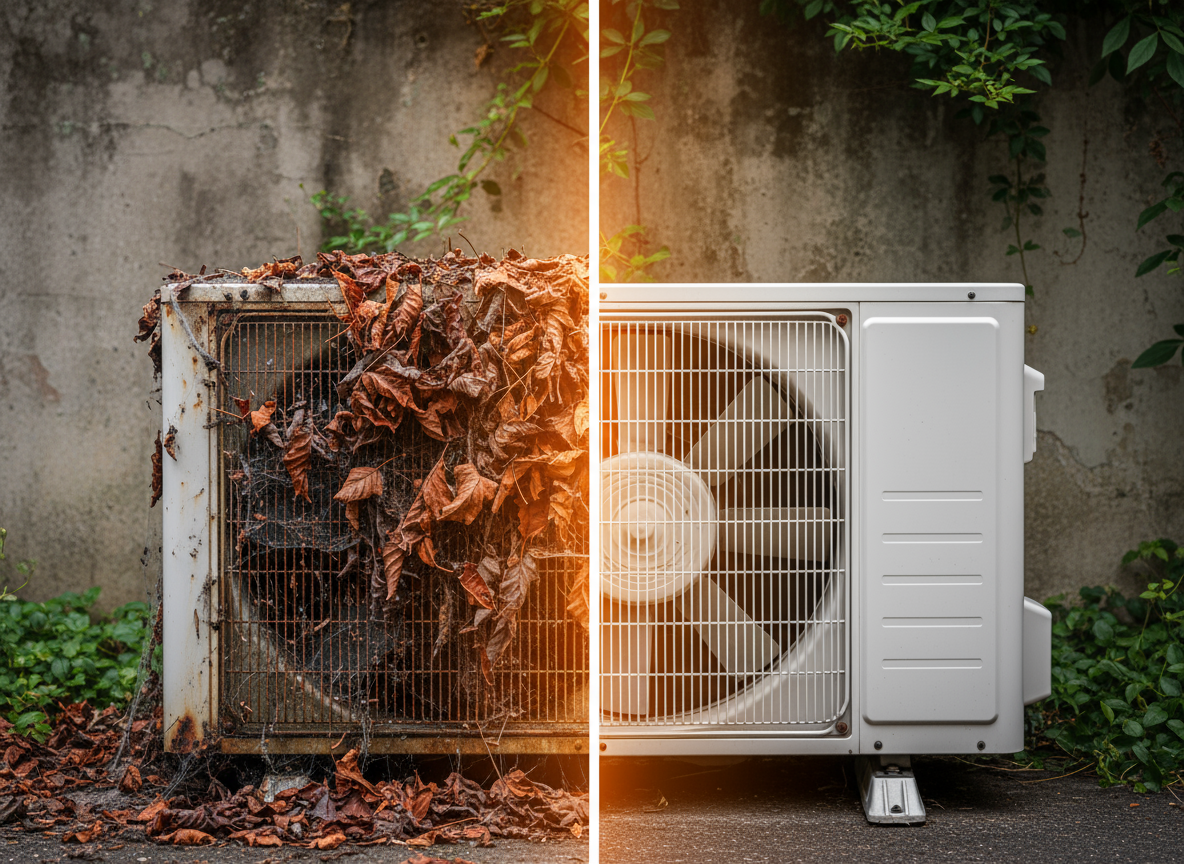

How consistent care extends your heat pump’s life

Regular maintenance prevents small issues from turning into structural failures: it’s not an extra expense, but rather a form of investment that safeguards system performance, reduces surprises, and ensures continuous home comfort (Daikin). Dust, leaves, and condensate are silent enemies that, if neglected, undermine the unit’s thermal and mechanical balance.

- Clean fans and coils reduce stress on the motor and compressor.

- Clear drains prevent standing water and corrosion of lower parts.

- Periodic sensor checks ensure correct defrost cycles and service continuity.

A well-maintained system can operate optimally for over ten years, keeping performance very close to day-one levels. The difference between a neglected unit and a cared-for one shows not only in lifespan, but also in comfort: more stable temperatures, reduced noise, and fewer emergency call-outs.

Consumption, efficiency, and savings: the tangible benefits

Every maintenance action directly affects energy consumption. A dirty or poorly tuned heat pump requires more energy to reach the same temperature, leading to higher bills. Conversely, a clean, balanced system works efficiently, fully leveraging its ability to recover heat from the outdoor environment (US Department of Energy).

- Energy savings: up to 25% less consumption compared to an unmaintained system (NREL).

- Steady efficiency: uniform temperatures and immediate comfort even during winter peaks (Daikin).

- Lower emissions: less energy required means a smaller environmental footprint.

- Lower repair costs (up to 40%): failures are prevented rather than fixed (CoolSys).

Maintenance is therefore a true energy-optimization strategy: it improves performance and reduces waste, ensuring a positive economic balance season after season.

☑ Clear your heat pump of leaves and obstructions

The heat pump continuously exchanges air with the environment: if air can’t circulate, efficiency drops, consumption rises, and the risk of faults increases. A quick, targeted seasonal cleaning restores airflow and prevents frost and standing water.

The microclimate around the heat pump: why it matters

Around the heat pump, a microclimate forms made up of air currents, humidity, shade, and wind-blown debris. Leaves, pine needles, dust, or nests can obstruct airflow through the coils and grilles, forcing the unit to work harder to achieve the same result.

- Obstructions: reduce heat exchange and lengthen defrost cycles.

- Humidity and standing water: encourage frost/ice on fans and finned coil.

- Wind and turbulence: if deflected by nearby objects, can re-enter the discharge and “recycle” cold air.

Goal: keep the air intakes on every side clear and ensure an unobstructed discharge path, with a flat, draining surface beneath the heat pump.

Seasonal cleaning: tools and small tips

Before you start: switch off the system and disconnect the power supply. Avoid aggressive tools: the coil fins are delicate.

- Gloves and goggles: recommended personal protection.

- Soft brush or wide paintbrush: to remove leaves and dust without bending fins.

- Low-power vacuum: useful for light debris in the grilles.

- Slightly damp microfiber cloth: for the outer casing and smooth surfaces.

- Low-pressure water (if needed): never pressure washers or direct jets on the motor or control board.

- Thin bottle brush: to pass between fins with gentle, vertical motions.

Quick checklist (5 minutes)

- Gather leaves and branches in the surrounding area.

- Visually inspect grilles, fan, and coil.

- Remove debris with brush/low-power vacuum.

- Clean the casing and check that the screws are tight.

- Ensure the condensate drain isn’t clogged.

Avoid: solvents, oily products, pressure washers, and bending the fins. If there’s stubborn dirt or deformed fins, consider calling a technician.

Ventilation and protection: keeping balance without over-covering

Good external protection must never stifle the unit: air must freely enter and exit. Solid covers or those too close to the grilles cause cold-air recirculation and increase defrost cycles.

- Clearances: leave space around the sides and in front of the airstream to avoid recirculation.

- Draining support: stable, non-absorbent base; encourages condensate disposal.

- “Louvered” or perforated protection: shields from leaves and debris while allowing ventilation.

- No tight waterproof tarps: they encourage condensation and corrosion, especially in winter.

- Orientation: if possible, avoid frontal obstacles (tall walls, dense hedges) in front of the discharge.

The ideal balance is simple: shield dirt and driving rain, but always ensure ample ventilation. This way the unit exchanges heat better, defrosts less, and consumes less.

☑ Check water drainage

One of the least visible yet most important functions of the heat pump is managing condensate water. In summer it forms during dehumidification; in winter during defrost cycles: in both cases, efficient drainage is essential to avoid standing water, ice, and corrosion of metal parts.

The water path: where risks hide

Water produced by defrosting or condensation must flow freely through pipes or drainage channels, but it often encounters unexpected obstacles: leaves, soil residue, or simply an incorrect base slope. If the flow slows, standing water can quickly turn to ice, compromising the operation of the fans and coil.

- Clogged drain pipes: prevent correct condensate evacuation.

- Base without slope: water tends to pool under the unit.

- Residue and debris: encourage mold growth or corrosion on metal brackets.

- Lack of channelling: water ends up against the wall or under the unit, damaging paving or façade.

A simple visual inspection can already reveal a lot: if you notice limescale halos, signs of oxidation, or persistent dripping under the unit, drainage likely isn’t working as it should.

Prevent standing water and ice with correct placement

The position of the outdoor unit directly affects its ability to dispose of water. Ideally, the heat pump should be installed on a raised, draining base that allows water to flow freely outward. Even a few centimeters of height make a difference, especially during freezes.

- Minimum slope: at least 1–2° toward the drain point to facilitate natural flow.

- Ground clearance: raise the unit 10–15 cm to avoid build-up and ease evaporation.

- Bracket check: ensure there are no bends or sags altering the slope.

- Clear area around the drain: avoid very fine gravel or leaves that could block flow.

If the unit is in a shaded or poorly ventilated spot, it helps to promote natural drainage with a small extension hose or a channel that directs water to a more open point, reducing the risk of localized freezing.

Recommended materials and supports for efficient drainage

Not all bases are equal: material and structure can improve or worsen water runoff. Modern solutions favor stable, insulating, weather-resistant supports that combine functionality and durability.

- PVC or high-density polyethylene bases: lightweight, durable, and with non-slip surfaces.

- Galvanized or painted metal brackets: ideal for lifting the unit off the ground and aiding runoff.

- Composite supports: isolate from vibrations and are unaffected by moisture.

- Integrated drainage channels: automatically direct water outward.

Avoid improvised supports like porous concrete blocks or raw wood: they absorb moisture, encourage mold, and deteriorate over time. A solid, well-designed base, on the other hand, improves stability, extends the system’s life, and reduces maintenance.

In short: the right base and good drainage aren’t aesthetic details, but fundamental components of your heat pump’s seasonal performance.

☑ Protect the system from the first frosts

When temperatures drop below zero, the heat pump is called to peak performance. However, severe cold can become its worst enemy if the outdoor unit isn’t properly protected. Frost, rain, and wind put mechanical and electronic components under strain, reducing efficiency and accelerating wear. Prevention extends the system’s life and guarantees full functionality even in the harshest months.

Frost, rain, wind: the three enemies of the outdoor unit

The outdoor unit lives outside year-round, exposed to weather that, over time, can compromise its thermal and mechanical balance. The main risk factors are three:

- Frost: during defrost cycles, residual water can solidify on fans or grilles. This increases motor load and can cause vibrations or partial blockage.

- Rain: if persistent, it penetrates gaps, oxidizes metal parts, and accelerates corrosion. Internal humidity also encourages condensation and micro-droplets that can affect sensors.

- Wind: carries debris, dust, and leaves into the unit; if strong, it can also create air returns that impair ventilation.

These elements may seem harmless individually, but together they form an aggressive micro-environment that, day after day, impacts overall system efficiency. Proper protection is therefore a preventive choice, not an aesthetic one.

Lightweight protection strategies: from placement to ventilated covers

Protecting the outdoor unit doesn’t mean sealing it airtight: the goal is to shield it from the elements without hindering ventilation. The most effective strategies are simple and “lightweight,” designed to suit the context and improve the system’s longevity.

- Smart placement: choose a sheltered but well-ventilated area, preferably under a canopy or near a wall that reduces direct exposure to rain and wind.

- Ventilated covers: perforated or louvered solutions that protect against the weather while still allowing proper airflow. Ideal for autumn and winter, they help keep the surface temperature consistent.

- Debris barriers: light grilles or protective panels that prevent leaf and twig build-up without compromising efficiency.

- Clearances and height off the ground: keeping the unit raised and clear on the sides helps avoid standing water and supports drainage during defrost cycles.

When adopted together, these measures create a natural barrier against external agents, keeping the system in optimal condition even during intense cold spells.

The long-term value of discreet protection

Well-designed protection isn’t just a guarantee of efficiency, but also an investment in aesthetics and function. Modern ventilated covers, made of durable materials with clean design, integrate harmoniously with outdoor environments without weighing down the façade or garden.

Over the long term, good protection:

- Reduces wear on external and mechanical components.

- Keeps thermal efficiency steady even after years of use.

- Avoids extraordinary maintenance due to corrosion or infiltration.

- Contributes to acoustic comfort, slightly dampening unit noise.

Ultimately, protecting the system doesn’t mean covering it up, but accompanying it through the cold season with lightweight, breathable, durable solutions that preserve balance, efficiency, and design over time.

Reduce maintenance with a ventilated cover

Even though maintenance remains essential for proper heat-pump operation, it can be made simpler and less frequent with proper protection. A ventilated cover shields the outdoor unit from rain, wind, and debris without restricting airflow: a solution that doesn’t replace maintenance, but optimizes it, reducing extraordinary call-outs and keeping seasonal efficiency steady.

Over time, this kind of protection helps to:

- avoid leaf and dirt build-up on the grilles,

- prevent ice and corrosion on metal surfaces,

- keep operating temperature more stable,

- and protect sensitive components from weather and moisture.

In practice, the heat pump stays cleaner, runs with less mechanical stress, and requires less care time.

A concrete example: Box Air Klima’s Big Blade

Among the most compelling solutions for protecting heat pumps, Big Blade by Box Air Klima strikes a successful balance between functionality and design. Designed and made in Italy, this cover is built to shield the outdoor unit from rain, wind, and debris without ever compromising ventilation. The composite aluminum structure with 316L stainless steel elements guarantees strength and durability, while the ventilated design maintains natural airflow, avoiding standing water and moisture build-up even in the toughest conditions.

Big Blade’s strength is its versatility. It can be wall-mounted, floor-mounted against the wall, or installed free-standing, easily adapting to any type of system and outdoor setup. It’s available in six different sizes — from XL to VXL — to accommodate even large units, and it’s among the largest and most robust heat-pump covers on the market today. This flexibility enables effective protection even for non-standard equipment or more complex installations, without sacrificing aesthetics or functionality.

The horizontal slats, precisely angled and spaced, deflect rain and protect the unit from wind while still allowing the air needed for correct heat-pump operation to circulate. Composite aluminum also helps dampen rain resonance, making the environment quieter and tidier.

More than an accessory, Big Blade is a smart technical solution: it reduces the need for frequent cleaning, protects exposed components, and keeps the system’s seasonal efficiency steady. In essence, it lets you perform maintenance less often and with less effort, without sacrificing aesthetics or performance. It’s the kind of protection you hardly notice, yet it truly makes a difference over time.

Smart protection, simplified maintenance

A cover like Big Blade doesn’t eliminate the need for seasonal checks, but it makes them lighter and more predictable. It reduces the amount of dirt and moisture that reaches the unit, preserves more delicate materials, and protects the system from thermal shock or water ingress.

In other words, it reduces the maintenance required and optimizes performance over time. It’s a discreet, technical, durable solution — a concrete example of how design can contribute to sustainability and comfort, simplifying life for anyone who uses a heat pump every day.

Signals not to ignore before winter

Even the most efficient heat pump can show subtle warning signs before the cold sets in. Spotting them in time lets you intervene with small adjustments instead of costly repairs. Autumn is the perfect time to listen to and observe the system: what seems like a simple noise or a slight leak today could become a serious problem in the coldest months.

Unusual noises or fluctuating performance

A healthy heat pump runs smoothly and quietly. If you notice metallic hums, irregular vibrations, or sudden hissing, you might be dealing with dirt build-up on the fans or loose mounts. In some cases, louder or cyclical noises can signal an issue with the compressor or bearings.

- Continuous vibrations: check the unit’s mounting and the stability of its base.

- Metallic hum: may come from loose grilles or panels.

- Rhythmic noise at start-up: possible fan imbalance or partial ice on the blades.

Fluctuating performance — alternating warm and cool air or long times to reach temperature — is also a red flag: it often indicates dirty sensors, imperfect refrigerant balance, or partially obstructed coils.

Drips, moisture, or frost in unusual places

A little condensate under the outdoor unit is normal, but persistent dripping or frost where it shouldn’t be deserves attention. These signs indicate drainage isn’t optimal or that the machine is running defrost cycles too frequently.

- Drips near cables or electrical panels: may signal infiltration or internal condensation.

- Localized frost on the lower section: likely standing water not draining properly.

- Constant moisture around mounting brackets: risk of corrosion or loss of thermal insulation.

Don’t ignore these details: small pockets of moisture can turn into sheets of ice as frost arrives, interfering with proper airflow and fan movement.

When it’s best to call a technician

Some tasks — like exterior cleaning or checking drainage — are within everyone’s reach. But if you notice performance drops, unusual odors, or error codes on the display, it’s wise to rely on a professional. A trained technician can check the refrigeration circuit, gas pressure, and sensor calibration.

- Persistent noises even after cleaning → possible mechanical or alignment issue.

- Efficiency drop despite clean filters → check refrigerant or a clogged coil.

- Excessive ice build-up → verify defrost cycle or temperature probe.

- Display errors → electronic diagnostics to identify the fault code.

Acting before winter helps you avoid being left without heating at the worst time. Professional autumn maintenance is the simplest way to ensure efficiency, safety, and steady comfort throughout the cold season.