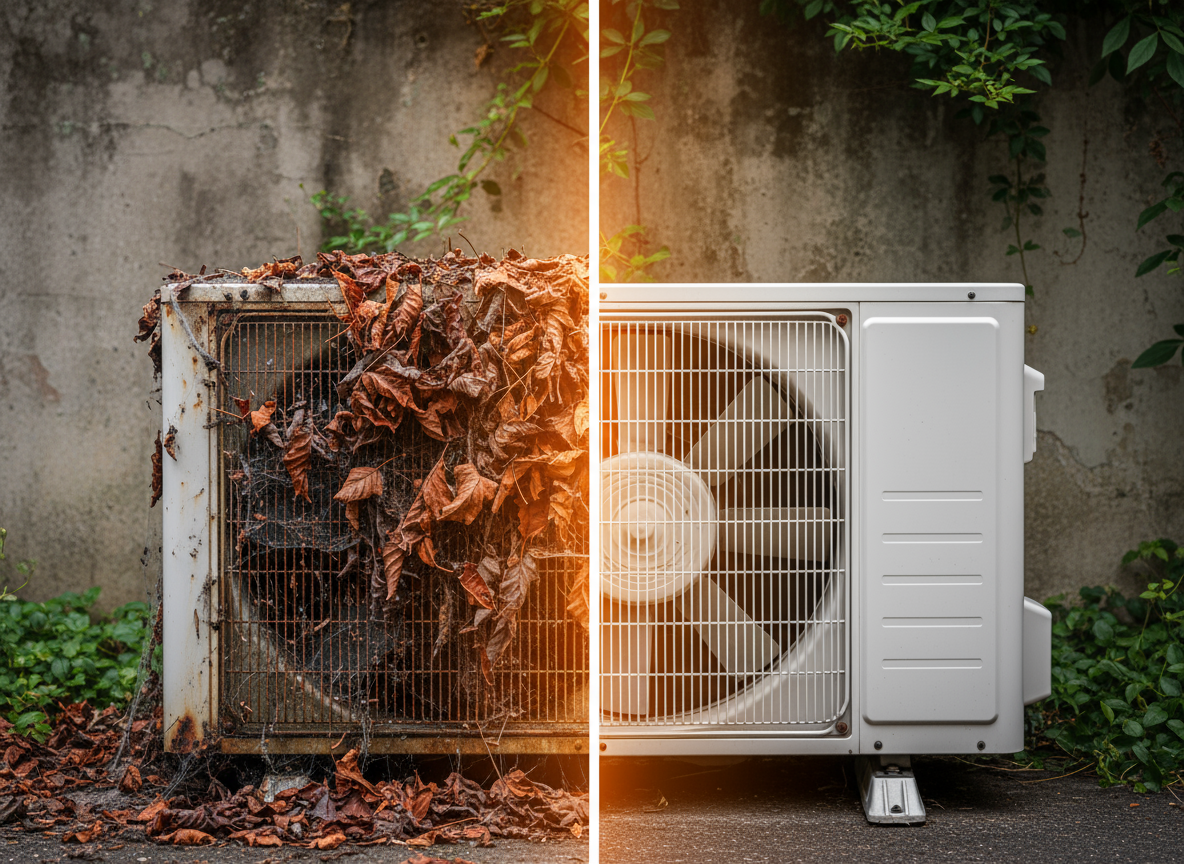

Heat pumps and outdoor air conditioners keep working even when conditions become truly harsh. And that’s where snow and ice stop being “just weather” and become an operational issue: wind-driven buildup, defrost water that freezes again, drainage that gets complicated.

The solution, however, is not to “cover” the unit with improvised or airtight solutions. A properly designed cover is meant to shield the unit from direct weather and keep the area neater and easier to manage, without turning airflow into a problem and without making maintenance inconvenient. In other words: protection, yes—but with distances, air paths and access points designed on purpose.

If you’ve ever had to check the unit after a snowfall or found ice around the base, you already know what we mean. Bringing order to these effects is the first step to choosing protection that truly helps—without unnecessary compromises.

What really happens in winter: 3 real problems (not theory)

When heat pump, snow and ice combine, it’s not just about “dirt” or “aesthetics”. The point is that some winter dynamics can turn into tougher operating conditions: the unit runs, but often less steadily, with more instability and more need for attention.

Problem 1 — Defrost and refreezing: water turns into ice (and builds up)

In winter the unit periodically enters defrost to clear frost from the heat exchanger. This process quickly melts frost/snow near the coil and produces water that runs down toward the base and surrounding areas. If temperatures stay low or humidity is high, that water refreezes quickly. When the sequence repeats (melt → drain → refreeze), ice tends to build up in multiple spots.

What it means for the heat pump

- Less stable operation: constantly changing conditions around the unit (water/ice) make performance less consistent.

- More frequent or “heavier” defrost cycles: the unit may need to manage frost/ice more often, interrupting normal operation to defrost.

- A more critical base area: ice around the base and drainage zones can complicate water runoff and “mess” with winter operation.

What it means for you

- More attention and checks: more frequent inspections after snowfalls and during very cold/humid days.

- Less consistent comfort (in some setups): if defrost is frequent, output can feel less continuous.

- More awkward interventions: ice on the ground or near the base makes working harder and increases the time needed for checks or targeted cleaning.

Problem 2 — Wind-driven snow: deposits on the coil and grilles (airflow gets worse)

Wind-blown snow doesn’t settle “randomly”: it can collect right in front of the exchange surfaces and near intake/outlet areas. With repeated episodes, snow can create partial blockages or buildup that reduces the quality of airflow.

What it means for the heat pump

- Less effective heat exchange: if airflow is disrupted, the unit may work less efficiently.

- Higher tendency for frost/ice in critical conditions: humid air + cold + disturbed flow can worsen frost buildup.

- Reduced consistency: the unit may alternate “good” phases and tougher phases depending on buildup and exposure.

What it means for you

- Worse perceived performance on the toughest days: harder to maintain comfort, especially if the installation is very exposed.

- More “manual management”: local removal of snow/buildup from sensitive areas.

- More calls/visits for checks: not necessarily failures, but extra inspections because the unit “doesn’t feel like it usually does”.

Problem 3 — Drainage and work area: pooling, ground ice and more critical maintenance

Beyond snow, there’s water: defrost runoff, winter rain, condensation. In many installations, water needs to drain cleanly around the unit. If the area is prone to pooling or has unfavorable slopes, that water can refreeze and create ice zones around the installation.

What it means for the heat pump

- A more “hostile” operating environment: water and ice return cyclically, making winter management more complex.

- More sensitive runoff and base: if water doesn’t drain well, the area around the unit becomes a recurring weak point.

- Greater exposure to irregular conditions: the installation “doesn’t dry out”, increasing the chance of repeating the same issue after each defrost/rain.

What it means for you

- Less convenient and less safe access: ground ice near the unit makes any operation more delicate.

- Longer interventions: even a simple check takes more time if the area is icy or cluttered.

- More winter management stress: it’s rarely “fixed once and for all”—it tends to come back with weather and defrost cycles.

Protection guide: what you really need when snow and ice put the system to the test

After these three issues, one thing becomes clear: in winter you don’t need “something that covers”. You need protection that works on two fronts at the same time:

- Reduce direct impact from snow, wind and freezing conditions on the most exposed areas (without chasing the illusion of total closure).

- Don’t create new problems: restricted airflow, inconvenient maintenance, complicated access, a more critical work area.

In practice, sensible winter protection has to respect a few simple rules.

What well-made protection must guarantee

- Mechanical shielding from direct weather: especially in installations exposed to wind and snow.

- Correct air paths and clearances: the unit must work with free airflow—no “plugging” and no obstacles.

- Real accessibility: inspection, checks and routine maintenance must remain convenient, without having to dismantle anything.

- Managing the area around the base: defrost produces water, so the area must remain easy to monitor.

- Outdoor stability and durability: wind, humidity, frost and accidental impacts are not exceptions in winter—they’re the scenario.

Avoid “false solutions” (and their risks)

1) Improvised covers: tarps, DIY boxes, random panels

They look like a quick fix because they “protect” visually. But they often introduce issues because they are not designed with clearances and airflow in mind.

Typical risks

- Airflow restrictions or partial choke points (often not obvious), leading to less stable operation.

- Buildup where you don’t see it right away: snow and ice can still get into the wrong places, while you lose quick access.

- Slower maintenance: if you have to remove improvised elements to check the unit, time increases (and it often gets postponed).

- Wind instability and material degradation: winter wind + moisture + freezing conditions quickly stress solutions not designed for outdoor use.

2) “Airtight” or overly closed covers: the risk is turning airflow into the problem

The intuitive idea is: “the more I close, the more I protect”. In reality, excessive closure can disrupt airflow and turn protection into an obstacle.

Typical risks

- Air recirculation or stagnation near outlet/intake zones, with less efficient heat exchange.

- More irregular behavior on critical days: humidity, frost and freezing conditions aren’t managed by “sealing”, but by letting the system breathe correctly.

- Worse access: if the cover is a closed “shell”, every check becomes more inconvenient and winter management gets worse instead of better.

Big Blade Box Air Klima: winter protection without the “plug effect”

Big Blade is the Box Air Klima cover designed to protect heat pumps (and large outdoor units) without compromising how they work. It is a cover with a registered design, developed to shield direct weather while keeping proper airflow, accessibility and a more orderly management of the area around the unit.

- Materials and structure: composite aluminum panels and supporting components/elements in 316L stainless steel, with powder coating for outdoor use.

- Airflow: geometry designed to respect airflow and avoid stagnation (not a closed box).

- Sizes: available in multiple sizes (XL, XXL, 3XL, 5XL, VL, VXL).

- Colors: White (RAL 9010) and Anthracite (RAL 7016), special colors on request.

- Made in Italy.

- To be assembled by the customer: shipped as a kit with instructions and hardware included.

Concrete benefits for heat pump users

- More peace of mind during snow and freezing days: the installation remains easier to manage, even when conditions are critical.

- Fewer checks and “quick” interventions: reduces the need to remove buildup or frequently check exposed areas.

- More consistent comfort when the system is very exposed: helps limit external conditions that make operation more irregular.

- A tidier outdoor area all season long: less mess and buildup around the unit.

Concrete advantages for installers and maintenance technicians

- Faster, less “complicated” interventions: practical access to inspection points, without removing improvised or awkward solutions.

- A more professional, better-valued finished job: a cleaner, more orderly installation—especially on high-value units and exposed positions.

- Easier upsell to justify and defend: it’s not “aesthetics”, but protection built around airflow, accessibility and winter management.

- Fewer check requests linked to harsh external conditions: in snowy or windy environments, it helps reduce situations that trigger repeated checks and unplanned interventions.

FAQ

Does Big Blade reduce heat pump performance?

No, if the cover is chosen and installed correctly. Big Blade is designed to protect without creating a “plug effect”, while keeping proper airflow and accessibility.

Are snow and ice really a problem for a heat pump?

They can be, especially with ground installations or very exposed setups: wind-driven snow, defrost water that refreezes, and difficult drainage increase winter management and the need for checks.

Does an airtight cover protect more?

Generally no: closing too much can turn airflow into a problem and make maintenance inconvenient. Useful protection shields direct weather without penalizing airflow and access.

Is a tarp or an improvised solution better?

It’s a risky choice: it often doesn’t respect clearances and airflow, it can worsen access, and it can degrade quickly with wind, moisture and freezing conditions. In winter, the goal isn’t to cover “something”, but to protect with criteria.

Is Big Blade suitable for very large heat pumps?

Yes. The range includes multiple sizes (XL, XXL, 3XL, 5XL, VL, VXL) to cover large installations and footprints.

Is it available in multiple colors?

Yes: White (RAL 9010) and Anthracite (RAL 7016). Special colors are available on request.

Can it be installed on the wall or on the ground?

The Box Air Klima range includes variants for different configurations (wall-mounted, floor-mounted against the wall, floor-mounted free-standing). The choice depends on the position and the real overall dimensions of the installation.

How can I quickly choose the right size?

To make it easier, we created a step-by-step configurator that guides you in a few clicks. The only information you need is:

- Installation position (wall-mounted / floor-mounted, against the wall / floor-mounted, free-standing)

- Real overall dimensions (heat pump + pipes)

Go to the configurator: Box Air Klima configurator